Posted in 3d Printer hacks Tagged 3d printer, injection molding, molding Post navigation It’s great for making parts for very small models like ’s current project, but this technique could be expanded to anything that needs a lot of small plastic parts with tight tolerances.

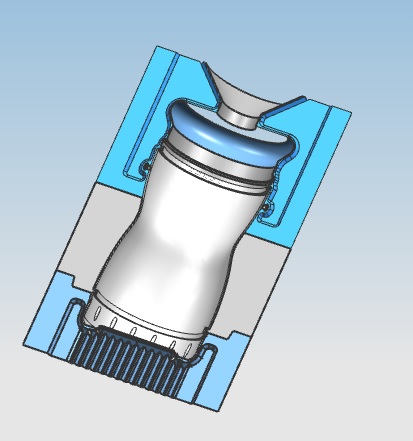

The resulting ‘print’ is as detailed as the best prints that will ever come off a resin printer. Once the mold is made, it’s a simple matter of holding the mold up to the nozzle of a printer and extruding a bit of plastic. Aside from that, it’s just silicone lubricant, dowels and LEGO to make sprues, and of course something to make a mold from. The tools required are RTV rubber, which is the most popular mold material around. Whether that plastic goes to a build platform or into a mold is beside the point but with a simple silicone mold, anyone can replicate extremely small parts with a tool every hackerspace already has. It takes plastic, melts it, and forces it through an orifice. has been working on a way to produce very small, very detailed parts for a while now, and realized the extruder of a 3D printer serves most of the functions of an injection molding machine. Why no one thought of using a 3D printer extruder to push plastic into a mold until now is something we’ll never know.

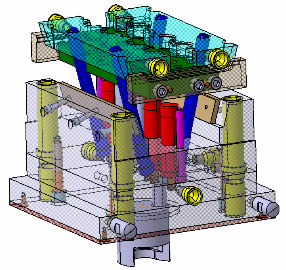

Injection molding machines are able to form very detailed plastic parts, simply by squirting plastic into a mold.

0 kommentar(er)

0 kommentar(er)